ASM / DEK Products

Our services

We offer

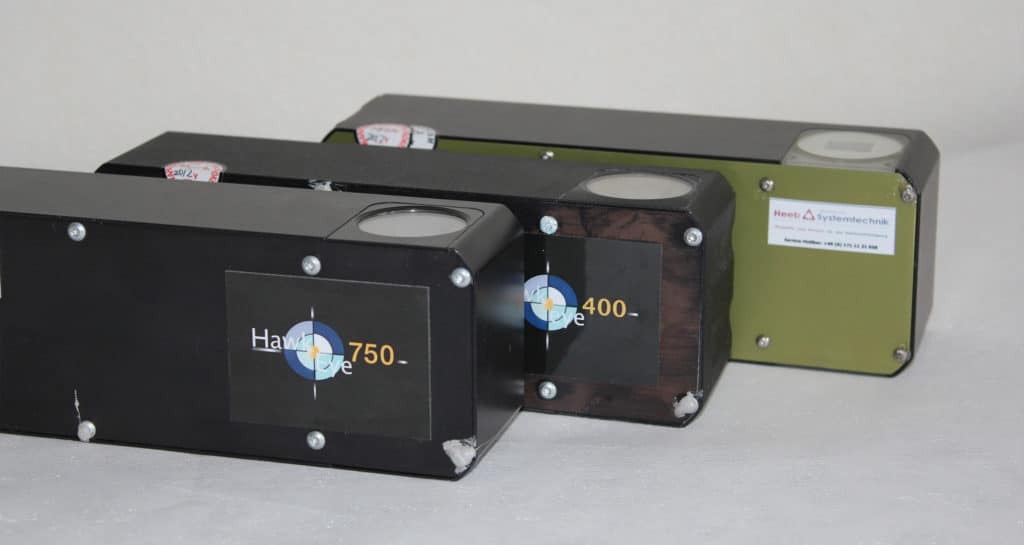

- new as well as refurbished cameras

- all HawkEye models

- 1:1 exchange service

- Upgrade from green / graphite camera to HawkEye and from HawkEye 750 to HawkEye 1700

- service, installation and calibration

Get to know all the qualities and advantages HawkEye cameras offer. Find all the details in the description below.

HawkEye - high speed cameras

With the HawkEye automatic solder paste inspection, a board can be checked for sufficient solder paste over a large area and in the shortest possible time. Die Closed-Loop-Anwendung bietet bei Erkennung fehlbedruckter Boards die Möglichkeit des Reworks in Echtzeit. The High- and Ultra-High-Speed cameras HawkEye® 750 and HawkEye® 1700 run at a maximum speed of 750 mm²/second respectively 1700 mm²/second.

The Advantages

- Improves print quality

- Quick and easy configuration

- Minimizes fault rate

- Cost-efficient alternative to inline AOI

- Upgrade optional for all DEK printers

- Good return of investment

Purpose

HawkEye® indicates whether a board is ready for production or not by scanning user-defined areas on the PCB. Parameters (go/no-go) are also userdefined and can be altered at any time based on requirements. The user can furthermore define the number of inspected PCBs (for example: every 3rd PCB only) to prevent interference with the line’s cycle time.

When a faulty print is detected, the machine stops and user can remove PCB or opt between the following recovering actions:

- Reprint

- Spend paste

- Clean screen

Operating principle

Paste deposit verification bases on the comparison of image data. Before production a “clean” PCB is used in order to define inspection areas.

When all areas are defined PCB goes into print. The camera operates verification by scanning the inspection areas and collecting image data. The user can now configure warning and error thresholds. PCB is removed from the machine and production is now ready to start.

During production all pre-defined areas of all printed PCBs are being scanned. The results are compared to pre-defined warning and error threshold and displayed on screen.

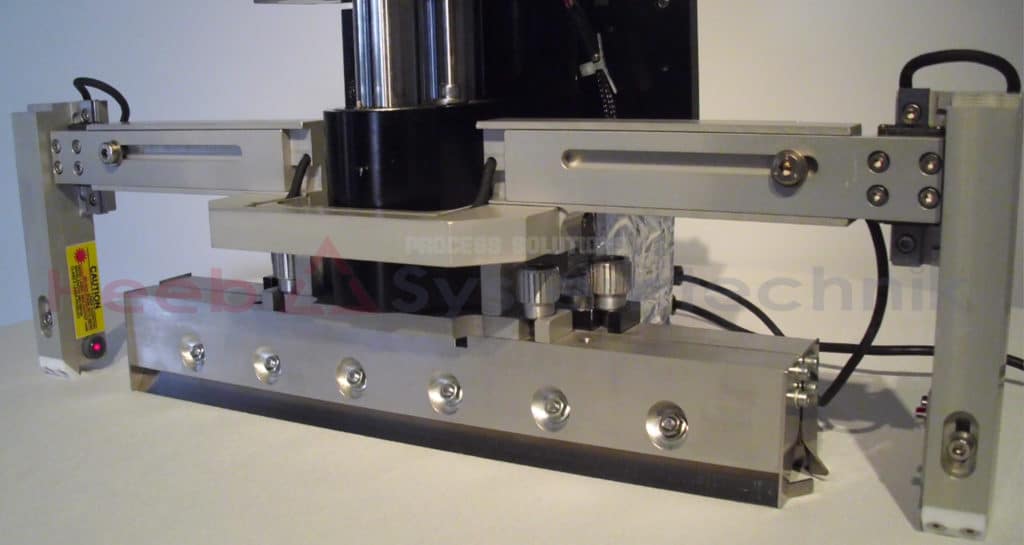

This upgrade includes a kit for the conversion to pneumatic screen clamps optional for all automatic DEK inline stencil printers with adjustable screen mount (ASM).

This upgrade includes a kit for the conversion to pneumatic screen clamps optional for all automatic DEK inline stencil printers with adjustable screen mount (ASM).

As this system works without a traction rope, which is always a weak point, it works maintenance free and waste free. The upgrade consists of 4 air cylinder units as well as all required small components. All geometrical measurements parallel those of the existing clamps which allows for the continuous and flawless functioning of the adjustable screen mount.

Advantages

- No machine down time caused by a tore traction rope ever again

- Minimal wearing of the system

- Quick adjustment to different frame thicknesses.

- Easy installation (approx. 1 h)

- Optional for all DEK printers with adjustable screen mount

- Good return of investment

Includes:

4 x pneumatic cylinder unit

4 x adapter plate for 30 mm frames

4 x adapter plate for 25 mm frames

1 x pressure control valve

1 x installation manual

1 x small components package

Supported frame thicknesses

25 mm, 30 mm, 40 mm

Supported machines

All DEK inline stencil printers with ASM, such as:

- DEK ELA / Horizon

- DEK Horizon 01/02/03

- DEK Horizon 01i/02i/03i

- DEK Europa / Galaxy

- DEK Horizon 01ix/02ix/03ix

The task of the paste height control is to keep the amount of paste on the stencil at a constant height during the printing process. For this purpose, the thickness of the paste roll on the stencil is measured during the printing process by means of a laser beam. The mode of operation is similar to that of a light barrier.

The task of the paste height control is to keep the amount of paste on the stencil at a constant height during the printing process. For this purpose, the thickness of the paste roll on the stencil is measured during the printing process by means of a laser beam. The mode of operation is similar to that of a light barrier.

If the paste level falls below the previously set level, solder paste is automatically/manually replenished. An alarm is triggered after the value has fallen below the threshold value several times in succession. The machine stops and gives an indication of insufficient solder paste.

Paste height control can prevent misprints and improve yields.

The Advantages

- Improves print quality - no printing on boards with insufficient paste

- Shortens the workflow through optimal refilling

- Minimal paste consumption

- Quick and easy configuration

- Upgrade optional for all DEK printers

- Good return of invest

Order now

Find what you need

in our webstore.